Craftsmanship Meets Innovation – The Design Vision and Material Technology Behind Our Composite Bathroom Accessories Set

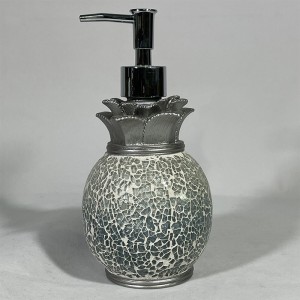

- With the continuous evolution of contemporary home aesthetics, how to better meet the diversified aesthetic needs of consumers is the fashion sensitivity that we, as a leading bathroom accessories set manufacturer, must have. We use innovative composite materials - high-quality resin combined with hand-inlaid glass to present a unique and novel bathroom accessories set.

- This composite material combination is inspired by the concept of "hardness and softness" commonly seen in architectural design. The flexibility of the resin provides excellent resistance to drops and pressure, while the glass part creates a sense of luxury and modern aesthetics through crack texture and light reflection.

- "Every detail is an expression of style. We believe that bathroom accessories can also become works of art."- Quote from the Product Design Director.

Endurance Under Pressure – Why Every Bathroom Accessories Set Must Undergo Extreme Testing

In order to ensure that our bathroom accessories set can adapt to the changing global transportation and use environment, we implement industry-leading high-low temperature cycling test and drop test. This is a reflection of our commitment to quality as a professional bathroom accessories set supplier.

1.High-low Temperature Cycling Test:

This test simulates the impact of various environmental conditions on the product during storage and use, assessing the aging resistance of composite materials under repeated high and low temperature cycles.It evaluates the material’s expansion coefficient under thermal changes and checks for any signs of cracking, deformation, delamination, or structural instability.The test also verifies the durability of surface coatings and adhesion processes under extreme weather conditions.

- Temperature Range: -20°C to +70°C

- Test Duration: 24 hours (1 hot-cold cycle every 8 hours)

- Test Cycles: 3 full cycles

- Pass Criteria: No structural cracks, secure adhesion, and no color fading or deterioration

2.Drop Test:

- Drop Height: 80 cm

- Test Directions: Each product set is dropped on 6 faces, 8 corners, and 12 edges

- Simulated Environment: Mimics the impact and shocks experienced during logistics, from warehouse handling to final delivery

- Pass Criteria: No breakage, no deformation, and all functional components operate normally

Through these standardized tests, we ensure that our products can confidently withstand the rigors of global shipping. This guarantees that the items delivered to your customers arrive in perfect condition—enhancing satisfaction and peace of mind.

Global-Ready Manufacturing from a Leading Bathroom Accessory Set Manufacturer

As a bathroom accessory set manufacturer with many years of export experience, we strictly follow the ISO and SGS testing system. The production process includes:

Raw material screening: High-density resin and artificially selected cracked glass

Injection molding and artificial inlay: Ensure that each product pattern is unique

UV coating protection: Increase wear resistance and waterproof

100% pre-delivery functional testing: Including pump head smoothness test, leak detection

Each set of bathroom accessories set has gone through 21 processes from design to delivery, meeting the needs of various occasions such as home, star-rated hotels, and resorts.

The Future of Bathrooms Begins with Every Detail

Whether you are a distributor, project purchaser, or brand retailer, we hope to become your long-term bathroom accessories set supplier or customized bathroom accessory set manufacturer partner.

This series of products not only meets your needs for product decoration, but also meets the international standards for safety and durability of actual product applications, giving your consumers peace of mind.

Post time: Apr-11-2025